ACM Panels for Fire-Resistant Façades

With occupant safety so paramount, designing a NFPA 285 compliant fire-resistant façade can seem daunting. Especially with so many building materials on the market today, what’s the easiest way to design a compliant exterior wall assembly to ensure building safety?

With a wide range of manufacturers and countless products contributing to the composition of exterior wall assemblies, achieving compliance is a complex challenge. A straightforward approach is to opt for fire-resistant core metal wall panels that have been tested to meet NFPA 285 standards.

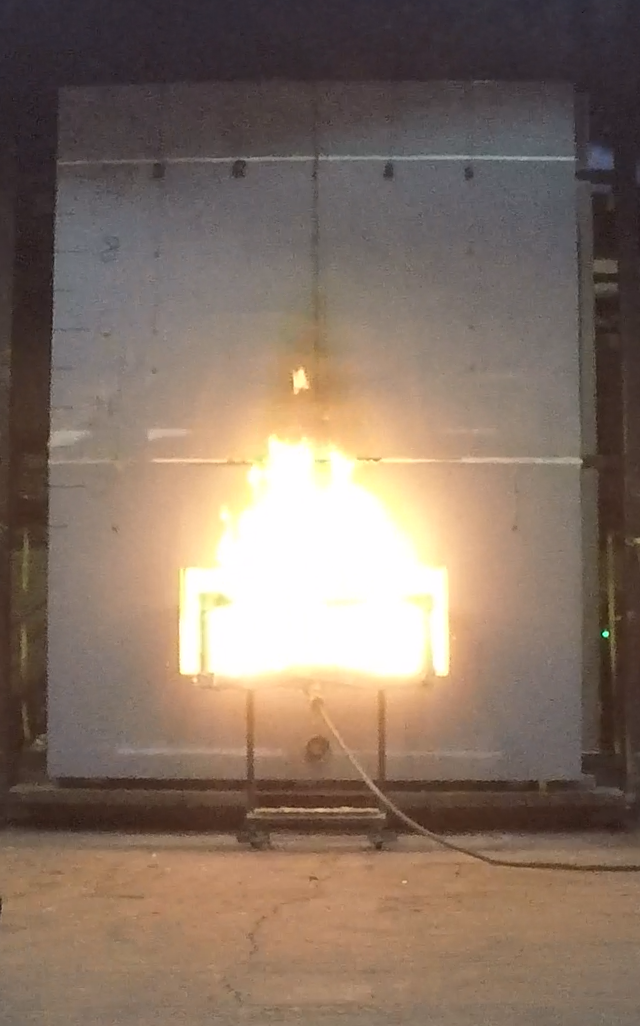

Fire Testing for Exterior Walls

Fire Testing for Exterior WallsPer the International Building Code, all building types with exterior walls above 40 ft tall require a fire-resistant façade in compliance with NFPA 285 testing. This fire test measures the flame propagation of combustible materials in an entire wall assembly, so swapping out any components in a proposed system requires re-testing or an engineering judgment before the installation. Note that other building elements may trigger the NFPA 285 requirement, so always check with local code officials to confirm the necessary tests and compliance for your build.

Numerous building materials can be combined to achieve NFPA 285 compliance, but not every wall assembly is created equal in terms of its ease of design and constructability. For hospitals, schools, hotels and other commercial buildings needing fire-resistance along with quality assurance and speed of construction, a prefabricated approach helps achieve all of these requirements.

Ensuring compliance with fire testing standards starts with selecting the right metal wall panel fabricator. Not all fabricators uphold the same standards, and the choice you make can have significant implications for safety and quality. A reliable fabricator will offer a fully tested system, enforce strict quality control measures, use only approved and tested components, and meticulously label each panel while ensuring thorough traceability of the entire system. This attention to detail provides peace of mind, knowing that the exterior of your building is equipped with trusted, compliant materials.

Dryvit’s Metalite® 8000 system is an Aluminum Composite Material (ACM) rainscreen panel, which when installed over an approved weather resistant barrier, acts as a certified moisture management system for the exterior building envelope. Manufactured in a controlled factory environment, this system begins with an ACM panel featuring a fire-resistant core. Our rigorous process is guided by the standards outlined in our Factory Audit Manual. This ensures that every component—including extrusions, sealants, tapes, and other accessories—is precisely integrated into the panels. The result is an exterior wall system that adheres strictly to the requirements of our ESR report and NFPA 285 fire testing, delivering unparalleled compliance and reliability. Metalite 8000 fire-rated panels are engineered for quick installation with minimal additional components, which eases the architectural details and trade interfaces for a simpler design and construction process.

Modern ACM systems like Metalite 8000 provide the fire-resistance and time-savings of a modern approach for streamlined NFPA 285 compliance. With comprehensive testing, proven installation methods and technical support from Dryvit, ACM panelization helps architects and contractors across the healthcare, educational, data centers and hospitality sectors meet the most demanding fire safety requirements while staying within project schedules and budgets.

The key to success lies in early planning, careful specification and precise installation. When these elements come together with high-quality wall panels and experienced teams, NFPA 285 compliance becomes a manageable part of the design/build process. Contact Dryvit to see how we can help deliver fire-resistance to your commercial construction projects.