EIFS vs. Stucco: What's the Difference?

When selecting materials for new construction, oftentimes, the choice for cladding comes down to using popular options like Exterior Insulation and Finish Systems (EIFS) or stucco.

To the casual observer, these two building materials might appear the same. However, there are several key differences that exist between the two that are crucial for architects and builders to know.

Let’s dive in to discover the actual differences between EIFS and stucco and determine which is the best option for your project.

EIFS, sometimes regarded as a “synthetic stucco,” was developed in Germany shortly after WWII and used to retrofit masonry walls. Because it provides continuous insulation, EIFS became popular as a means of retrofitting uninsulated structures without inconveniencing tenants or visitors.

By the late 1970s, EIFS became a widely used material for commercial buildings in the U.S. They gained additional popularity with the professional community as a way to meet the regulations around controlling the energy efficiency of commercial buildings.

Stucco has been the time-tested exterior plaster for thousands of years, dating back to Ancient Rome and Greek cultures. The earliest versions of stucco were well-known for being extremely durable and waterproof. Stucco gained popularity in the U.S. during the 19th century, most often being referred to as “plaster” and was primarily used on residential buildings and small commercial structures.

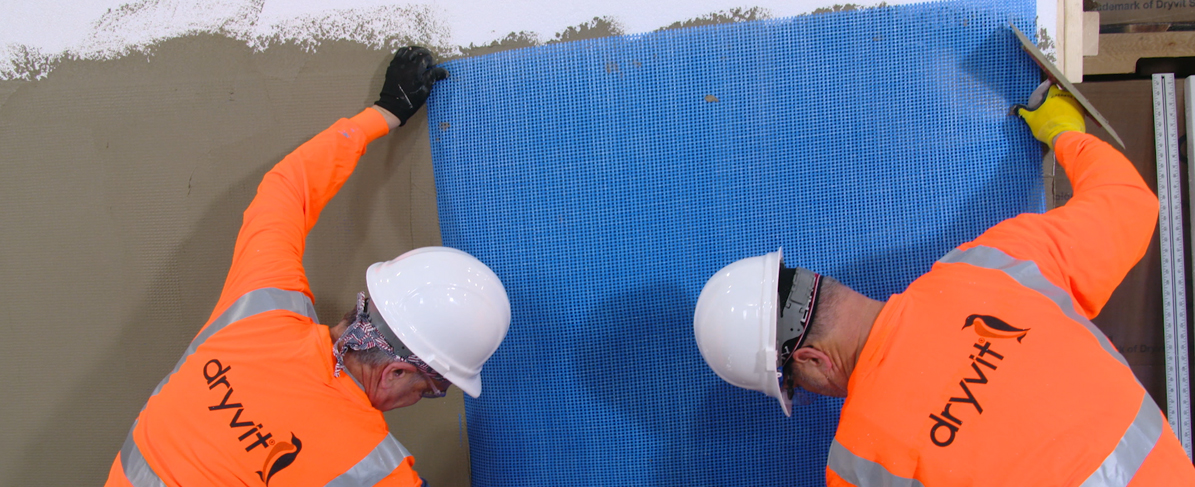

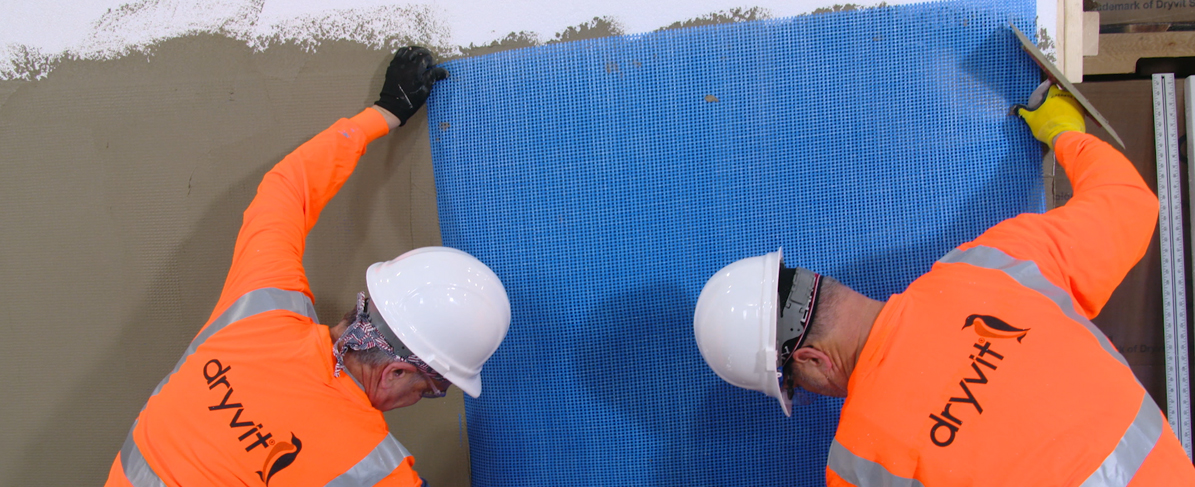

EIFS is made from sheets of rigid insulation board, adhesively or mechanically applied to an approved substrate or sheathing to provide an uninterrupted thermal barrier. First, a fluid-applied air and water-resistive barrier is applied to the substrate to provide a control layer for the management of both liquid and vapor moisture and air leakage.

The next layer consists of insulation protected by scalable, fiberglass-reinforced mesh, available in various weights per sq. yard, that’s embedded in an acrylic, cementitious base coat. The final, outer layer is an acrylic coating, which has nearly unlimited colors and textures and provides an architectural finish.

The materials used to develop stucco can usually be sourced locally, which helps with sustainability and transportation concerns. Stucco can be formed from the following substances. The amount of each ingredient depends on the type of coating being made:

Stucco is applied in numerous coats to achieve a set thickness, depending on the trim accessories used. Typically, it is applied in three coats over an expanded metal lath. It is frequently topped with an acrylic finish coat to minimize cracking and moisture absorption. This type of application can be labor-intensive with all the trim accessories used and requires specialized skills to complete the job.

Because EIFS is a complete system of layers and barriers, the advantages of EIFS far outweigh any disadvantages, especially when compared to stucco. Let’s take a closer look.

Pros of EIFS

Pros of EIFS

Let’s review some of the reasons why stucco has remained a popular cladding option throughout the centuries, as well as some drawbacks that come with this type of material.

Overall, when you consider the maintenance, durability, and energy-efficient aspects of EIFS, it is absolutely worth the investment long term. When installed correctly, EIFS meets or exceeds the same expectations that stucco is known for — without cracking and buckling.

No matter what solution you choose, Tremco is ready to help with your next EIFS or stucco project. Contact our team to get started today, and let us help you find the best cladding option for your next build.