Spanning Gaps in Insulation of Dryvit EIFS Walls

The thermal performance and energy efficiency of EIFS walls lies in their continuous insulation (CI), so careful application is critical to prevent any thermal breaks or air leakage. For all Dryvit Outsulation systems, the specification requires the EPS insulation boards be butted tightly to each other to maintain the continuity of the wall’s insulation. If, for any reason, the insulation board joints are not tight together, all gaps greater than 1/16 in. (1.6 mm) must be filled. Here are two ways to appropriately fill the gaps between the foam boards.

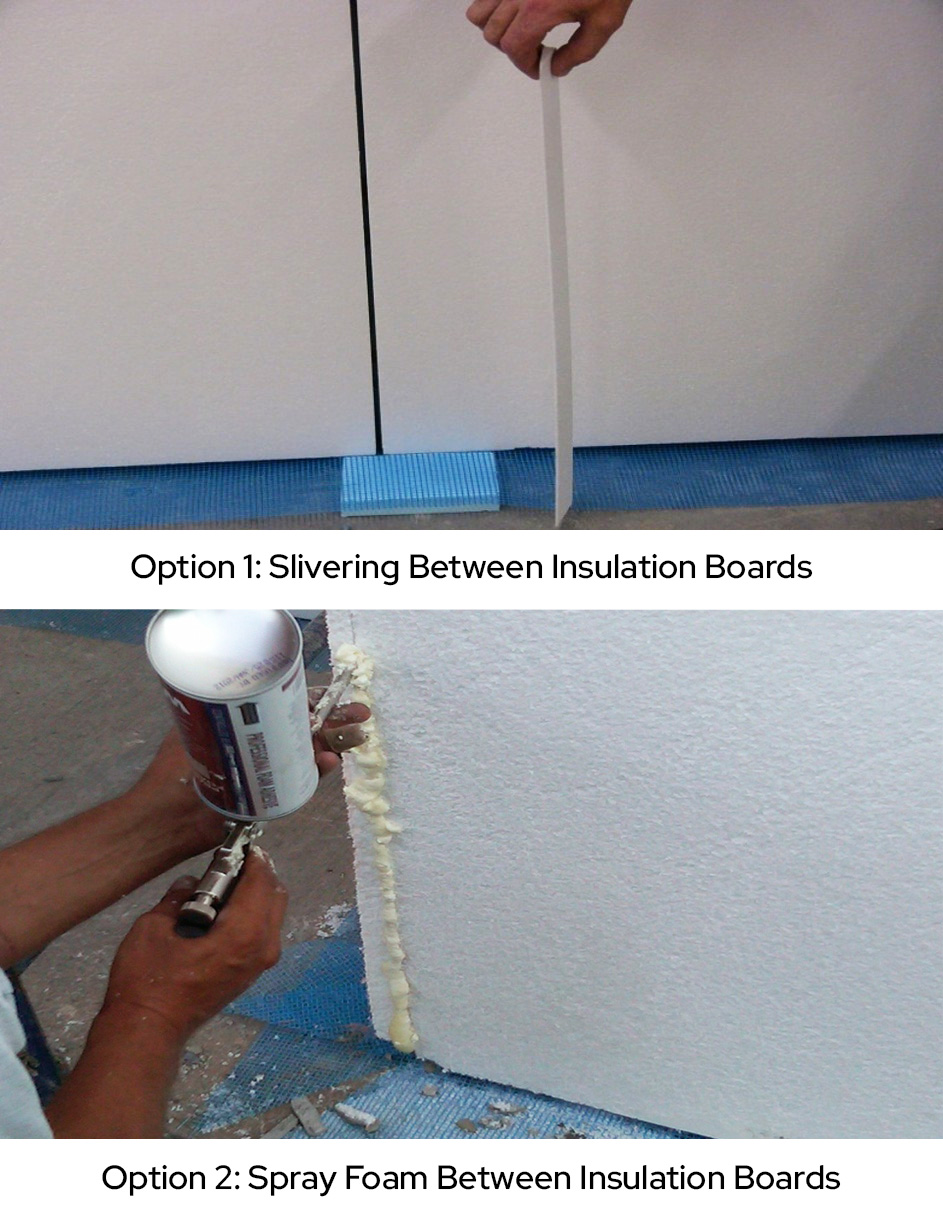

Option 1: Slivering Between Insulation Boards

Option 1: Slivering Between Insulation BoardsSlivers of EPS foam insulation can be cut and placed tightly to fill any openings in the joint between insulation boards. This process is the preferred gap filling method for insulation since it can be used under all conditions.

Alternatively, an approved spray foam expanding insulation, such as Tremco’s ExoAir LEF low-expanding polyurethane foam, can seal between insulation boards. Dryvt has found that gaps up to ¼ in. wide can be filled with this product without affecting the performance or aesthetics of the finished wall.

The spray foam should be injected into the gap as far back to the substrate as possible, but not less than half the thickness of the EPS board. After it cures, installers should slice off the excess material using a knife or trowel edge prior to rasping the surface of the EPS. Any material that may come loose during the rasping process must be reapplied. Environmental factors may affect the curing of the spray foam, so adequate time and site conditions must be allowed before continuing the system application.

Reference Dryvit’s Technical Bulletin here for more details on using expanding foam insulation to fill gaps between EPS boards.