Introductory Guide to Offsite Construction

Welcome to Offsite 101, your guide to offsite, in-plant and prefab construction methods.

Welcome to Offsite 101, your guide to offsite, in-plant and prefab construction methods.

Offsite construction practices are growing in popularity for building and restoring commercial projects to increase efficiency and reduce waste. Offsite methods, sometimes referred to as in-plant or prefab, also help to combat persistent industry challenges such as skilled labor shortages, material availability and price increases.

For instance, at the beginning of 2022, lumber prices tripled, placing a heavy burden on builders, architects and other industry stakeholders to cut costs and improve efficiencies wherever possible.

While offsite construction can mitigate these issues, it can require more upfront effort initially from the project owner and contractors, which can cause some apprehension. Despite the shift away from the status quo, many projects will see that the advantages of offsite construction methods far outweigh the added coordination.

Here’s everything you need to know about permanent offsite construction, including key advantages, what to consider before starting the process and how to get project stakeholders on board.

Offsite construction and prefabrication involve some or all of a building being constructed in a factory, then delivered to the project site to be installed.

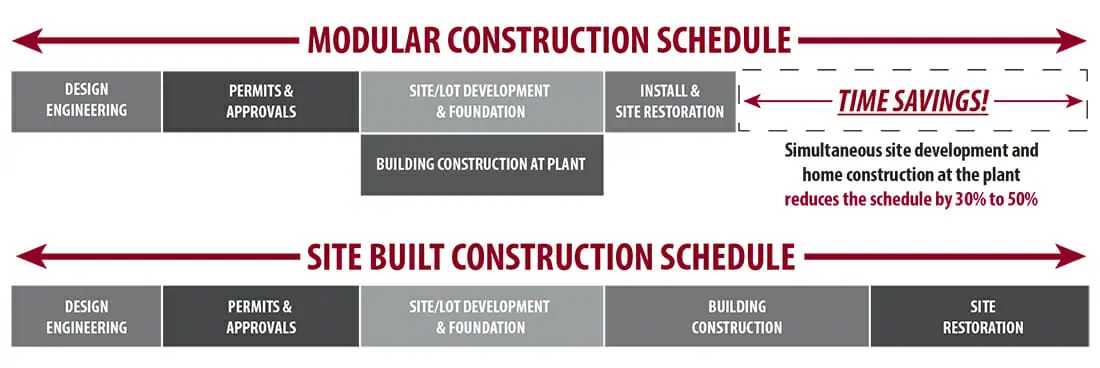

This process allows site development work (excavation, concrete foundation, etc.) and structural element installation to continue, while simultaneously building the modular elements off-site. Constructing numerous parts of a building at the same time regardless of weather conditions reduces the overall project timeline.

There are two main types of offsite construction: 2D modular wall panels used to complete the interior and/or exterior walls of the building, and 3D volumetric modular units that consist of entire rooms or sections of a building.

2D Prefabricated Panels

2D Prefabricated Panels

2D prefabricated panels, also known as prefab walls or panelized wall systems, bring together layers of a building’s wall assembly in a factory for easy transport and installation on the job site. Prefabricated exterior wall panels can include continuous insulation (CI), drainage, weather barriers, structural steel framing, window and door openings and other system components. Exterior insulation and finishing systems (EIFS) can be direct-applied but are also available as EIFS panels to expedite the dry-in process. Similarly, insulated wall panels, which can reference interior or exterior walls, are common to speed and simplify insulation install.

Buildings with prefabricated walls that include architectural exterior finishes are referred to as architectural wall panels or as having a panelized façade. These systems, such as Dryvit’s Modulite CI panels, can be used for new construction and exterior renovations to overclad a building, reduce thermal bridging and offer a customized façade with limitless finish options.

Once the pieces are delivered to the job site, workers attach the panels to the building exterior. With this process, contractors dry in the building faster than with standard construction, allowing interior trades to complete their work sooner. Typically, electrical, plumbing and HVAC services are not completed in the factory, so the final installation should factor in this extra time on site. Learn more about the benefits of CI panels here.

3D modular units are larger, 3-dimensional rooms or a series of rooms, constructed in a factory before delivery. The front-end fabrication process makes 3D volumetric units very efficient and can be the most cost-effective option for new construction, particularly in repeatable assemblies like hotel rooms and apartments. However, this does not mean that the layout, interior and exterior finishes of each module must be identical. These designs can differ from unit to unit to create any desired building aesthetic.

3D modular units are quite large, making delivery to the destination more expensive. It’s also important to note that each state has different shipping restrictions, so a travel route will need to be established well before the “oversize load” leaves the factory.

Once the shipment arrives, the assembly process tends to be less labor-intensive compared to using 2D panels and traditional onsite construction. These details can be assessed and accounted for during the design phase.

Offsite construction is not an all-or-nothing decision. Hybrid models, where part of a building is constructed in a factory, while others are completed on site, are both achievable and common. Each project will have its own unique design, timing and jobsite considerations that will dictate the best balance between panelization, modular and traditional construction methods.

In fact, in some cases, it can even be more efficient to utilize them all. For instance, common areas of an office building or hotel could be constructed on-site with the individual rooms delivered as 3D pods and the building façade installed as panels. Another example of a hybrid construction model is a mixed-use structure. Known as a podium building, the bottom one or two levels are built as a concrete podium with features like parking garages or retail stores. These components are built on-site as part of the foundation of the building. Then, modular apartment units are constructed in-plant and later stacked on top of the podium for residential living. There are countless offsite and traditional construction combinations that can be customized to suit the needs of nearly any project.

Design decisions need to be made upfront with modular building to ensure proper sequencing with the transition from the factory to the jobsite. This offers the advantage of a fairly firm budget from the beginning of the project. There’s rarely any ‘scope creep’, which can otherwise lead to cost overages in a traditional construction project. There’s also a decreased chance that market volatility will impact pricing for materials and labor since the project is finished over a shorter time span.

Utilizing an industrialized in-plant approach to construction brings a new level of efficiency to the market. More processes are automated in a controlled environment, and steps can be repeated to reduce time. A McKinsey report found that modular building cut project schedules by as much as 50% and cut costs by as much as 20%.

Offsite construction is quickly gaining a reputation for its sustainable practices. With offsite projects, there tend to be less material waste compared to fully onsite construction jobs. In fact, one study found there is up to 83% less waste generated in modular construction.

With the majority of the work in an offsite construction project done indoors, there are fewer aspects of the process at the mercy of the weather. Factory-built elements can be completed any time of the year, regardless of the outdoor environmental factors.

Plus, modular units and panels are assembled around the same time that onsite work begins. In most construction, concrete is required to cure for a minimum of 28 days before additional work can be started. By leveraging offsite construction, work can continue in a factory during that 28-day period. Everything is happening simultaneously to help reduce the overall project timeline. Once the units are completed in the factory, they can be installed on-site in a wider range of environmental conditions since most of the liquid materials, such as sealants and air barriers, have already cured and will not be affected by changing temperatures or precipitation.

By minimizing the amount of onsite work, modular construction reduces disruption to area residents and, in the case of a restoration project, existing building occupants. This process also benefits projects in crowded urban areas with little laydown room for excess equipment, scaffolding and building materials. For projects using prefabricated wall panels or 3D panels, the units can be delivered to the job site in the order in which they will be installed, minimizing the need for storage or staging space.

The construction industry is facing a clear labor crisis. A survey by the U.S. Chamber of Commerce revealed that 55% of contractors have a high level of difficulty finding skilled workers. Using building components built off-site relieves the burden of having to source a large team to complete the construction process.

A factory offers a more controlled and consistent environment than a construction site. Work is frequently done at bench height, with panels laid horizontally, as opposed to workers operating from scaffolds or aerial lifts while building on-site. Plus, with consistent temperatures, lighting and overall processes, in-plant practices create a safer working environment and reduced liability concerns.

In fact, a report from Dodge Data & Analytics found that 85% of general contractors and 86% of sub-contractors saw an increase in safety when using offsite construction compared to traditional methods. Additionally, working indoors minimizes weather-related moisture infiltration into the wall systems, which can cause mold and mildew growth and subsequent air quality issues when the building is in use.

Higher Quality

Higher QualityPrefabrication is mostly a reiterative process, which enables greater quality control and reduces the chance of defects, re-work and callbacks. Plus, while units assembled in a plant are of course constructed to meet or exceed building codes, they’re often built with even greater durability than onsite elements because they need to withstand the movement and forces associated with transportation. This higher quality assurance brings peace of mind for all involved parties.

A streamlined construction timeline means a faster path to revenue. The sooner occupants can get in, the sooner the owner or developer can see their return on investment. This speed also minimizes the risk of market fluctuations impacting the ability to fill units and helps improve cash flow since funds aren’t tied up for as long.

When you’re just starting to explore offsite construction, you may wonder how each project stakeholder will be impacted. After all, industry veterans may not be keen to stray from the methods they’re most familiar with. See below for details on how each party is affected during a prefabricated building approach.

While it can be a learning curve for the general contractor to track both the on-site and the prefabrication timelines, many contractors prefer an offsite approach to differentiate themselves during the bid process and potentially win more projects. Another benefit of offsite construction for contractors is that the job site can be safer when the primary elements have already been constructed elsewhere. The speed of installation and QA/QC from factory-assembly also allows them to complete more projects faster without compromising building performance or integrity.

One major change for architects with modular design is the shift to communicating with the factory. Regular visits by the design team during the production process allow them to review ongoing work and make any necessary changes before it’s too late. In addition to designing the modular pieces themselves, architects should also design elements with the transportation and assembly restrictions in mind. With this collaborative approach, the manufacturer, fabricator and architect should clearly define their roles and responsibilities at the onset of the project to minimize any miscommunications or ambiguities.

The installation team’s responsibilities will depend on whether the project has 2D panels, 3D units or both. While some of their typical scope of work may be completed in the factory by another party, installers are critical to the on-site assembly and connection of the various systems. There are also other building components that cannot be constructed in a factory, which will require field applicators before and after the prefabricated elements arrive at the job site. For example, installers will be needed for features like balconies, parking decks and most interior finishes.

Building owners stand to benefit the most from offsite construction since there is the potential for large cost and time savings. However, they should be prepared to make key decisions early in the process and understand that design flexibility only gets more difficulty and more expensive once the fabrication process begins. For instance, exterior finishes, textures and colors, as well as space planning, interior finishing details and service integrations, should be finalized in the initial stages of planning.

Both onsite and offsite construction methods require detailed planning and communication, but the processes look a little different.

One key difference all parties will notice is that more decisions need to be made early on since modular fabrication happens quickly and often simultaneously with other stages of the construction process. And once construction begins, the ability to make changes is limited.

To assist with this, select an experienced offsite construction company that can identify necessary decisions, implement a timeline and efficiently manage that process from beginning to end.

All parties also need to be clear on who is responsible for the financial and insurance obligations of the prefabrication process. The financing can be challenging in terms of the lender’s definition of “property.” When the units are still in the factory setting, lenders often won’t release funds until they are delivered to the job site.

This can be problematic for developers and building owners who may need up to 50% of the loan upfront. It is recommended to look to nontraditional lenders, such as real estate investment funds, for their nontraditional construction method.

There are also national and local financing options available as it applies to renovating existing buildings for greater energy efficiency and Deep Energy Retrofit projects.

Is this project well-suited for modular or panelized design and fabrication? Every job will be different. For instance, areas with good or reliable weather and easy access to raw materials may not benefit as much from the time and cost savings that come with off-site construction. It’s helpful to do a cost-benefit analysis of both options before making a decision. Additionally, buildings that are complex and don’t have repetitive units may be better suited for traditional onsite construction.

Once the design team and the manufacturing team complete the units, the delivery and installation processes can begin. The job site must be staged to receive the shipment, with grading, foundation and utility work completed in advance.

When the components arrive, they need to be lifted into place. 3D units are typically moved with a tower crane, while 2D panels have more equipment options depending on their size, from forklifts to truck mounted hydraulic cranes to crawler cranes.

The installation team then connects the modules and secures them to the foundation or framing as needed. Mate lines must be sealed together to prevent water and air leaks. Foam expansion joints are an ideal solution for a weathertight seal between prefabricated units. If not included in the original factory design, then the exterior cladding may also be installed at this stage.

Next, the sub-contractors will finalize the electrical, plumbing and heating and cooling connections. They’ll also take care of any remaining interior and exterior finishes, such as stairs, ramps, parking lots, roofs and landscaping.

It is possible to transition from a traditional construction project to an offsite one, but the decision should be made as early as possible to take full advantage of its benefits. Here are some important steps to consider when thinking about switching to the prefab route.

Modular buildings with 3D units can be slightly larger than traditionally constructed buildings because the stacking approach essentially doubles the thickness of the interior walls. The construction site needs to have enough square footage to accommodate the extra space; otherwise, the pods could be too large to fit. Modular units and prefabricated panel sizes may also be limited by a government’s shipping restrictions. In addition, oversized loads can increase freight costs. Get estimates on the cost to transport the prefabricated components before making the final decision.

If you’re in the early stages of a project, it should be straightforward to convert the project plans to offsite construction. Talk to the architect to gauge feasibility. Ideally, they’ll have some familiarity with modular design for an easier transition and to make sure all specifications are up to code. According to McGraw-Hill Construction, 76% of architects report having at least some project experience with modular buildings. Building material manufacturers and the fabricators should also be involved with the process of converting plans to ensure products are being incorporated appropriately.

Talk to the General Contractor

Talk to the General ContractorConnecting prefabricated units at the job site requires a specific installation method. The GC can help find subcontractors who have experience working on a modular building to streamline assembly and trade sequencing.

Since the construction site and manufacturing facility may be under different county or state regulations, the inspection process may differ as well. Early inspections are performed at the factory with inspectors from that jurisdiction for both 3D and 2D units. If this is your first time working with a fabricator or your first offsite project, it is best practice for the architect, builder or GC, and owner to visit the manufacturing facility and monitor progress. Once the components are delivered and assembled, a local inspector completes the on-site inspections.

Specifying offsite building materials has many similarities to on-site materials. Like any traditional project, it’s important to check product availability and lead times to make sure they won’t slow down the construction schedule. If the design-build team is unsure where to start, talk to a local modular unit or panel fabricator. Most facilities can provide their list of frequently used products and recommended building material manufacturers.

Tremco CPG brands, including Dryvit and Tremco Commercial Sealants and Waterproofing, supply high-performance building materials for constructing, restoring and maintaining traditional buildings as well 3D modular and 2D panel assemblies. They specialize in solutions for all sides of the building envelope and its connections, such as:

They also manufacture their own CI panels and sealant technologies to provide comprehensive, compatible systems with one point of contact. Dryvit’s Modulite™ prefabricated solutions come with numerous architectural finishing options and are ideal for both fully offsite and hybrid projects.

It’s easier to make the shift to prefabrication when you can incorporate brands you know and trust. Contact a local representative today to get started.