Understanding MCM Panels in Building Design

Metal Composite Material (MCM) systems play a crucial role in contemporary architectural design, offering a modern, prefabricated wall solution with exceptional versatility, durability and performance for building envelopes. This blog post will provide an overview of MCM exterior wall panels, their fabrication, code requirements and design considerations.

MCM panels can be constructed of aluminum, copper, zinc, stainless steel or titanium. The most prevalent metal used in MCM systems is an Aluminum Composite Material, so these panels are known as ACM panels. While all ACMs are metal panels, not all metal panels are ACMs.

Regardless of the metal used, MCMs are delivered to the jobsite pre-painted and ready for installation on the building to minimize the required lay-down room.

MCM panels are known to be environmentally friendly as they are manufactured from recycled metal. For example, aluminum composite panels can contain upwards of 70% recycled material.

MCM systems are most commonly deployed within drained and back-ventilated (D/BV) rainscreen assemblies. In this scenario, the wall assembly features 3 layers. Attached to the structural framing is the inner layer of sheathing, an air barrier and insulation. The outer layer is the MCM cladding, serving as the primary weather barrier and aesthetic element of the façade. Vertical drainage in the system creates an air cavity, the third layer, which is critical for proper moisture removal and ventilation. MCM panels in this rainscreen application can block 90% of bulk water, while the remaining 10% evaporates or drains naturally through gravity.

Note that not all drainage planes are rain screens, nor are all MCM systems rainscreen systems. Only assemblies with a ventilated cavity that promotes active airflow qualify as true rain screens. Performance is typically validated by ASTM E283, E330, E331 and especially AAMA 509 standards, assessing water infiltration and ventilation properties.

MCM panels are prefabricated in a factory, which improves quality control, reduces waste, minimizes weather-related delays and altogether streamlines the construction process. Panels can be designed in virtually any shape, with the widest dimension typically around 60 ft. The size is dictated by curtain wall integration, structural loads and design intent.

The metal sheets arrive to the fabrication plant with the color already on it, so after the metal panels are cut, routed and folded, they can be shipped to the jobsite for installation.

Like any exterior cladding, MCM wall panels must comply with building codes and several key test standards.

NFPA 285 tests the fire propagation in exterior non-load bearing wall assemblies. Compliance is required for walls over 40 ft high or containing plastic insulation. Since full wall assemblies, not individual components, are tested for NFPA 285 compliance, substituting materials requires retesting or an engineering judgment (EJ) to ensure proper fire protection. Dryvit’s Metalite® 8000 panel system, for example, has already been tested with full NFPA 285 compliance, compared to other systems that may rely on EJs.

As a primary weather barrier, MCM panels should be tested to ASTM E283, E330 and E331 to evaluate their air leakage, structural performance and water penetration respectively under various environmental conditions.

MCM panels from Dryvit pass all of these tests for proven performance in any climate. Be sure to check local building codes for additional considerations and confirm with your MCM fabricator that their systems comply.

Installation of MCM Panels

Installation of MCM PanelsFabricators and manufacturers are essential to educating installers on system-specific installation requirements. Many of them provide training, design assistance and field support to aid projects from concept to completion.

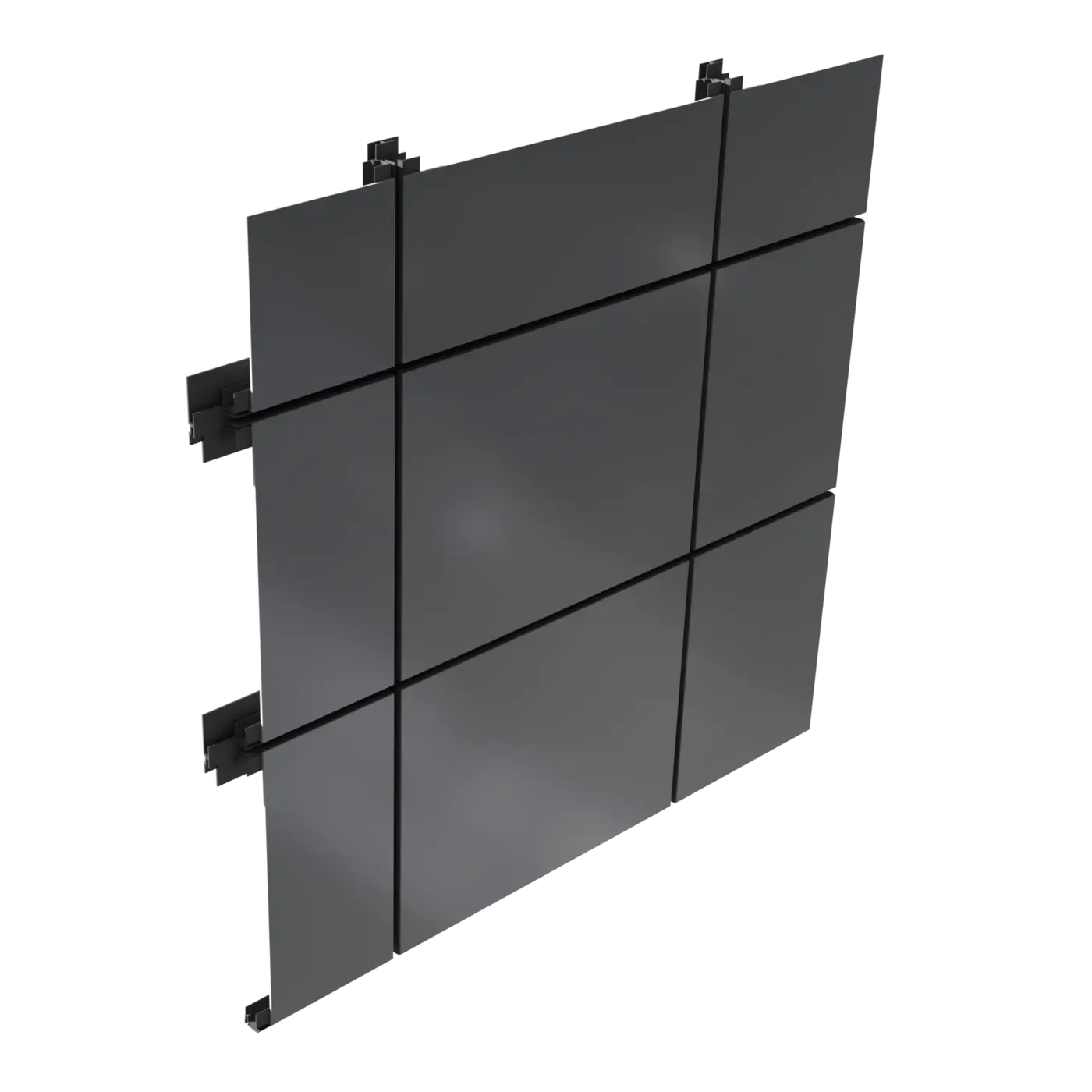

MCM sheets are turned into panels by adding extrusions using one of three common attachment methods: riveted, rivetless (structurally glazed), or combination extrusions. Continuous perimeter extrusions are favored over intermittent clips for superior rigidity and wind-load resistance. The panels are then fastened to the building using sub-framing or girts.

With the typical weight of an MCM panel between 2 and 3 lb/sq ft, multiple installers on a lift can hang each panel without the use of other heavy machinery. Workers should be careful to consider the orientation of each panel and the directionality of the finished coating for proper attachment and a cohesive aesthetic.

Metal Composite Material panels are beneficial to a project’s architects, contractor and owners. From the design perspective, these metal wall panels can be fabricated in various shapes and sizes for maximum versatility. There are also numerous color options to create a monochromatic façade or even custom patterns as different color panels are combined.

Many MCM wall systems even have built-in moisture management to ensure proper drainage. To simplify the wall assembly even further, designers can choose connected materials from the same manufacturer for proven compatibility. For example, air barriers, insulation, expansion joints and MCM panels can all be secured from Dryvit and Tremco.

An MCM panelized façade is durable and low maintenance, requiring only routine cleaning to keep their metallic finish. And building owners can rest easy knowing that the metal finish of some MCM panels can be warranted for up to 30 years.

For a long-lasting metal cladding, MCM systems are proven to deliver a high-performance and beautiful façade with built-in sustainability and strength. By understanding the options and opportunities with Metal Composite Material panels, design and construction professionals can maximize the time-savings, durability and visual impact of MCM systems on contemporary building exteriors.

To learn more, contact Dryvit today to find the MCM panel that’s best for your project.